What’s a printed circuit board (PCB)?

A printed circuit board (PCB) is a construction for assembling digital elements and their connections right into a unified circuit that permits electrical present to move between elements. The PCB baseboard is often manufactured from a inflexible nonconductive materials, though it can be constructed on a versatile base or on a base made up of each inflexible and versatile supplies. Digital elements reminiscent of diodes, inductors and transistors connect to the circuit board, and traces (electrical conduits) join elements.

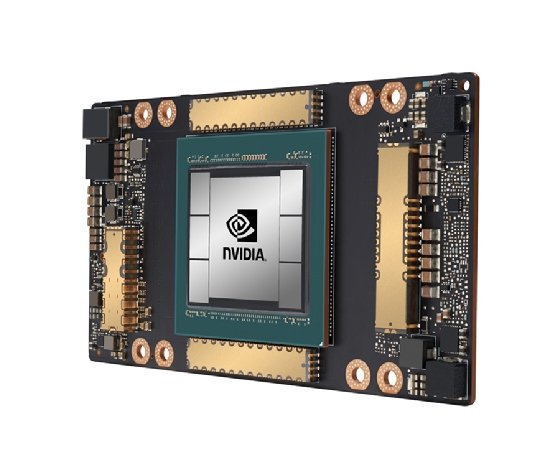

Printed circuit boards assist digital units of all kinds and sizes. For instance, many shopper merchandise comprise PCBs, together with laptops, tablets, smartphones and smartwatches, in addition to home equipment, leisure techniques and IoT units. PCBs additionally drive communication and navigation techniques and are present in industrial and medical gear, vehicles, plane and sea vessels.

Printed circuit board layers

A PCB might be single-layer, double-layer or multilayer. Single-layer PCBs are sometimes used for easy digital units reminiscent of house home equipment, whereas multilayer PCBs are typically constructed for extra complicated {hardware}, reminiscent of laptop graphics playing cards and motherboards. Double-layer PCBs enable for larger density than single-layer PCBs and are used for digital units reminiscent of automotive dashboards or LED lighting, for instance.

A PCB’s layer rely is usually primarily based on its variety of conductive layers. Nonetheless, a PCB additionally consists of different kinds of layers, that are laminated collectively in alternating patterns of conductive and insulating materials. Right this moment’s PCBs all the time comprise the next 4 kinds of layers:

- Substrate. That is the bottom, or core, layer. It’s sometimes a inflexible insulating materials reminiscent of FR-4, a fiberglass/epoxy composite. In some instances, the substrate is a versatile materials, normally plastic, which might fold or bend to accommodate house necessities. Versatile substrates also can face up to greater temperatures and different harsh situations. Some PCBs use a mixture of each inflexible and versatile substrate supplies.

- Conductive. This layer is normally constructed from a skinny sheet of copper. On a single-sided (or single-layer) PCB, there’s one conductive layer laminated to the substrate. On a double-sided (or double layer) PCB, there are two conductive layers, one on all sides of the substrate. A multilayer PCB alternates between the substrate and conductive layers.

- Solder masks. The conductive layer is roofed with a solder masks, a nonconductive materials that provides PCBs their inexperienced coloration, though different colours can be utilized. The solder masks acts as an insulator for the underlying traces which are etched within the conductive materials. The solder masks can also be utilized to the underside of a single-sided PCB.

- Silkscreen. This layer is solely the labeling that’s utilized to the PCB in spite of everything the opposite layers have been added. The labeling can embrace numbers, letters, symbols or different data that signifies the assorted capabilities of every connection level. The labeling is normally white, however different colours can be utilized.

A PCB is made up of a mixture of these 4 kinds of layers. The combo and its group varies relying on the PCB’s function. A single-layer PCB consists of certainly one of every of those 4 layers. A double-layer PCB consists of one substrate, however two of every of the opposite kinds of layers. A multilayer PCB will comprise a mixture of conductive and nonconductive layers, though the precise group can differ. In some instances, a multilayer PCB may additionally use prepreg as a layer. Prepreg is a dielectric materials that is sandwiched between two core layers or between core and conductor layers.

Printed circuit board elements

PCB elements use certainly one of two strategies to connect with the board: through-hole or surface-mount. By way of-hole elements have connecting wires (leads) that plug into holes within the board. The leads are soldered to the opposite aspect of the board. Floor-mount elements are soldered on to the identical aspect of the board. Right this moment’s PCBs are likely to favor surface-mount elements as a result of they require much less house and are extra environment friendly, though they’re tougher to assemble.

The PCB elements join to one another by way of traces, which facilitate communications between the elements. The traces are created from the conductive layer via a course of known as etching, which removes all of the copper from the conductive layer besides what is required for the traces.

A PCB can embrace a variety of elements, which differ relying on the board’s function. Among the extra frequent kinds of elements embrace the next:

- Battery. Supplies voltage to the PCB’s circuit, though many PCBs obtain their energy from exterior sources.

- Capacitor. Holds electrical cost after which releases it when it’s wanted within the PCB’s circuit.

- Diode. Ensures that the present flows in just one route, stopping it from flowing within the unsuitable route.

- Inductor. Shops vitality within the type of a magnetic area, which will help management the fluctuations within the electrical present flowing via the PCB.

- Resistor. Limits or regulates the circulate of electrical present within the PCB’s circuit by producing resistance to the present’s circulate.

- Sensor. Detects enter from the bodily setting — reminiscent of vibration, movement, acceleration or infrared mild — and responds to that enter by producing a corresponding sign.

- Swap. Switches the present on or off because it passes via the PCB’s circuit.

- Transistor. Amplifies or switches the digital sign passing via the PCB’s circuit.

Lots of immediately’s PCBs adhere to a high-density interconnect (HDI) design, which includes a greater wiring density than conventional PCBs. HDI circuit boards require much less house and might accommodate extra elements. The design additionally makes it attainable to create extra compact PCBs, which weigh much less and require fewer supplies. The HDI design is well-suited to be used instances the place house is a crucial issue, reminiscent of smartphones, house home equipment or medical implants.

Be taught the main kinds of server {hardware} and their execs and cons and discover the variations between CPU, GPU and DPU.