Open Platform Communications (OPC) is an interoperability customary for safe information change in industrial automation and different areas. It’s designed to be platform-independent so units from totally different distributors can change info. The unique customary was restricted to Microsoft applied sciences, so its software was restricted to Home windows programs, however the usual is now extra platform-independent, scalable and extensible.

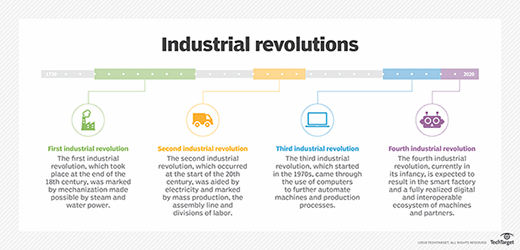

The OPC customary has come to play an important position in Trade 4.0, a motion towards sensible manufacturing that embraces digital transformation and cutting-edge applied sciences, together with synthetic intelligence (AI) and industrial web of issues (IIoT).

Trade 4.0 represents the fourth industrial revolution, which emphasizes communication and interoperability.

The OPC customary allows programs to speak extra effectively and successfully, making it doable to gather and analyze info from each a part of the manufacturing course of. This helps to interrupt down information silos, enhance effectivity and responsiveness, and facilitate higher enterprise selections.

Historical past of Open Platform Communications

In 1995, 4 industrial automation distributors launched a process pressure to standardize the data-access protocols throughout their units. On the time, these units predominantly ran Microsoft working programs. The duty pressure devised a plan to summary the communication protocols utilized in programmable logical controllers (PLCs), that are small, special-purpose computer systems extensively deployed in industrial environments to regulate manufacturing programs and processes.

The preliminary specification abstracted the protocols right into a standardized interface that converts learn/write requests between human-machine interface (HMI) and supervisory management and information acquisition (SCADA) programs. An HMI is a person interface that allows operators to work together with machines and programs through a PLC, and SCADA is a well-liked laptop structure generally used for industrial course of management. The OPC interface converts device-specific requests into generic OPC requests and converts generic OPC requests into device-specific requests.

In 1996, the duty pressure launched model 1.0 of the OPC customary, later dubbed OPC Basic. Not lengthy after, different {hardware} and software program distributors adopted the brand new customary. This led to the formation of the OPC Basis in 1996 to formalize compliance, certification, interoperability and validation procedures. The inspiration continues to create and preserve the OPC specification and guarantee compliance by way of certification testing.

OPC Basic specs

The primary model of the OPC customary was primarily based on the Distributed Element Object Mannequin (DCOM), a Microsoft expertise for exchanging information between software program elements throughout a community. Because the identify suggests, DCOM is a subset of the Element Object Mannequin (COM), an object-oriented method to creating binary software program elements.

Initially, the OPC acronym stood for OLE for Course of Management as a result of the Object Linking and Embedding (OLE) expertise performed such a key position in Home windows environments and subsequently the OPC customary. OLE is a Microsoft COM desktop expertise for embedding and linking paperwork and different software program objects.

The OPC Basis divides OPC Basic into three specs:

- OPC Knowledge Entry (OPC DA). First launched in 1996, the specification defines the OPC client-server structure for exchanging information. It particulars how software program can learn and write information, and the information sorts and buildings obtainable.

- OPC Alarms and Occasions (OPC AE). First launched in 1999, the specification describes the methods OPC server software program can monitor programs and ship alarms to consumer software program.

- OPC Historic Knowledge Entry (OPC HDA). First launched in 2001, the specification defines the queries and analytics that may be utilized to the historic time-stamped information collected from units.

In 1998, the OPC Basis started to transform the unique OPC DA specification to internet companies. Then, in 2006, the inspiration launched the OPC Unified Structure (OPC UA) specification, the following era of the OPC customary.

OPC Unified Structure specs

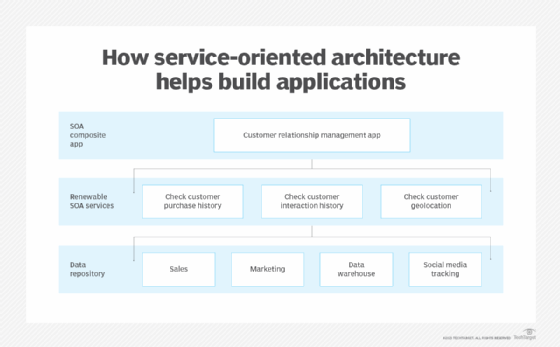

In 2006, the OPC Basis launched model 1.0 of OPC UA. The brand new customary was developed partly as a result of Microsoft was shifting away from DCOM towards a service-oriented structure (SOA). SOA is a software program design method that comes with reusable companies able to speaking throughout totally different platforms and languages.

On the time, many industries had already integrated SOA into their manufacturing processes. Distributors additionally wished to broaden their OPC software program to non-Home windows platforms, together with embedded units. The OPC UA customary sought to accommodate these developments, whereas nonetheless offering backward compatibility with OPC Basic.

OPC UA presents an extensible SOA framework designed to help a variety of platforms, from embedded microcontrollers to cloud infrastructure. It goes past OPC Basic by including a number of necessary capabilities:

- Platform independence throughout {hardware} architectures and working programs.

- Full mapping between the OPC Basic specs and the brand new OPC UA.

- Better safety by way of encryption, authentication and auditing.

- An extensible, multi-layered structure that helps the addition of latest options whereas sustaining backward compatibility with present merchandise.

- An info modeling framework that allows builders to mannequin and lengthen complicated multi-level information buildings.

The OPC UA customary, now at model 1.05, consists of 24 core elements, which have been revealed individually between 2021 and 2023. The OPC Basis additionally supplies downloadable COM proxy wrappers for integrating OPC UA and OPC Basic merchandise.

As of mid-2024, the OPC Basis claimed over 920 member corporations and 1000’s of OPC-compliant merchandise. Members embody leaders within the software program, {hardware}, industrial automation, machine-to-machine (M2M), sensible vitality, and discrete- and process-manufacturing sectors. Among the many most well-known corporations are Honeywell, IBM, Microsoft, Rockwell, SAP and Siemens.

Find out about potential IIoT use instances, in addition to extra of its benefits and challenges and discover the way to overcome frequent IIoT adoption points. Additionally, examine components to think about when securing industrial IoT networks.