Machine imaginative and prescient is the flexibility of a pc to see; it employs a number of video cameras, analog-to-digital conversion and digital sign processing. The ensuing knowledge goes to a pc or robotic controller. Machine imaginative and prescient is comparable in complexity to voice recognition.

Machine imaginative and prescient is usually conflated with the time period laptop imaginative and prescient. The expertise is commonly built-in with synthetic intelligence (AI), machine studying and deep studying to speed up picture processing.

How does machine imaginative and prescient work?

Machine imaginative and prescient makes use of cameras to seize visible info from the encircling atmosphere. It then processes the pictures utilizing a mix of {hardware} and software program and prepares the knowledge to be used in varied purposes. Machine imaginative and prescient expertise typically makes use of specialised optics to accumulate photographs. This method lets sure traits of the picture be processed, analyzed and measured.

For instance, a machine imaginative and prescient utility as a part of a producing system can be utilized to research a sure attribute of an element being manufactured on an meeting line. It may decide if the half meets product high quality standards and, if not, get rid of the half.

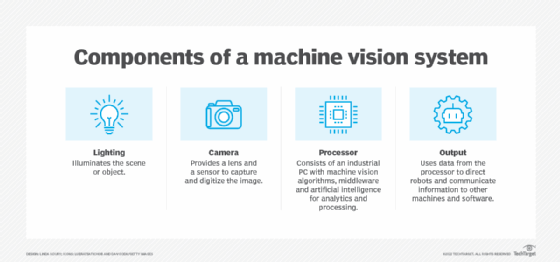

In manufacturing settings, machine imaginative and prescient programs usually want the next objects:

- Lighting. Lighting illuminates the article or scene to make its options seen.

- Lens. This captures the picture and delivers it to the sensor within the digital camera as mild.

- Seize board, body grabber or sensor. These gadgets work collectively to course of the picture from the digital camera and convert it to a digital format as pixels. Picture sensors convert mild into electrical indicators utilizing both complementary metal-oxide semiconductor expertise or a charge-coupled machine.

- Processor. The processor runs software program and associated algorithms that course of the digital picture and extract the required info.

- Communication. These programs allow the machine imaginative and prescient cameras and processing system to speak with different components of the larger system, often utilizing a discrete enter/output sign or a serial connection.

There are two kinds of cameras utilized in manufacturing machine imaginative and prescient:

- Space scan. These cameras take photos in a single body utilizing an oblong sensor. The variety of pixels within the sensor corresponds to the width and top of the picture. Space scan cameras are used for scanning objects which might be the identical dimension when it comes to width and top.

- Line scan. These cameras construct a picture pixel by pixel. They’re suited to taking photographs of things in movement or of irregular sizes. The sensor passes in a linear movement over an object when taking the image. Line scan cameras aren’t as restricted to particular resolutions the way in which space scan cameras are.

Digital camera lenses fluctuate in optical high quality. Two necessary specs in any imaginative and prescient system are the sensitivity and the decision of the lens, which have the next traits:

- Sensitivity is the flexibility of a machine to see in dim mild or to detect weak impulses at invisible wavelengths.

- Decision is the extent to which a machine can differentiate between objects.

Normally, the higher the decision, the extra confined the visual view. Sensitivity and backbone are interdependent. If different components are fixed, growing the sensitivity reduces the decision, and growing the decision reduces the sensitivity.

Human eyes are delicate to electromagnetic wavelengths starting from 390 to 770 nanometers. Video cameras will be delicate to a variety of wavelengths a lot wider than that. Some machine imaginative and prescient programs operate at infrared, ultraviolet or X-ray wavelengths.

Binocular, additionally referred to as stereo, machine imaginative and prescient requires a pc with a sophisticated processor. As well as, high-resolution cameras, a considerable amount of RAM and AI programming are required for depth notion.

Varieties of machine imaginative and prescient

Machine imaginative and prescient programs can function throughout varied dimensions primarily based on the precise wants and necessities of a selected utility.

Frequent kinds of machine imaginative and prescient programs embrace the next:

- 2D imaginative and prescient programs. These are probably the most broadly used programs that excel in sample recognition duties.

- 3D imaginative and prescient programs. Working in a number of dimensions, 3D imaginative and prescient programs present enhanced accuracy for measurement and inspection functions.

- Sensible camera-based imaginative and prescient programs. These programs use built-in cameras and software program to carry out a wide range of inspection-related duties.

- Compact imaginative and prescient programs. These programs are designed to be self-contained and might seamlessly combine into current gear and manufacturing processes.

- PC-based imaginative and prescient programs. Through the use of laptop processing and picture evaluation, these programs allow the execution of extra advanced visible inspection duties.

- Multispectral imaging. As an alternative choice to standard 2D imaging, this methodology includes capturing photographs at a number of wavelengths.

- Hyperspectral imaging. Much like multispectral imaging, hyperspectral imaging captures photographs at a considerably bigger variety of wavelengths, facilitating detailed evaluation of spectral knowledge.

- Variable magnification lenses. Outfitted with adjustable magnification ranges, these lenses present higher flexibility in finishing up inspection duties.

How are machine imaginative and prescient programs used?

Machine imaginative and prescient purposes are utilized in a variety of industries to carry out varied duties, together with the next:

- Digital element evaluation. Machine imaginative and prescient is used within the development of circuit boards for duties similar to solder paste inspection and element placement.

- Optical character recognition (OCR). OCR permits a pc to extract printed or handwritten textual content from photographs.

- Handwriting and signature recognition. With these options, a pc can detect patterns in photographs of handwriting and signatures.

- Object recognition. Within the automotive trade, self-driving vehicles use object recognition on photographs taken by cameras to establish obstacles on the highway. Machine imaginative and prescient programs additionally decide the place of objects, similar to the correct placement of a label on a capsule bottle.

- Sample recognition. Medical imaging evaluation makes use of sample recognition to make diagnoses primarily based on applied sciences similar to magnetic resonance imaging, blood scans and mind scans.

- Supplies inspection. Machine imaginative and prescient capabilities in supplies inspection programs guarantee High quality management. Machine imaginative and prescient checks for flaws, defects and contaminants in a variety of supplies and merchandise. For instance, these programs can examine tablets and tablets for points throughout manufacturing.

- Forex inspection. Machine imaginative and prescient is used to research currencies to detect counterfeit notes.

- Merchandise counting. This functionality is used to tally objects similar to tablets in a packet or bottles in a case.

- Barcode monitoring. This frequent utility makes use of the capabilities of machine imaginative and prescient programs to learn and observe barcodes in actual time.

- Robotics. The usage of cameras for robotic guiding is a quickly rising space of machine imaginative and prescient. Each 2D and 3D cameras are necessary in instructing robots to deal with particular person or bulk elements successfully. These purposes present excessive return on funding by decreasing the requirement for bodily labor.

Advantages of machine imaginative and prescient

Frequent advantages of machine imaginative and prescient embrace the next:

- Removes human error. Though the human eye is spectacular, it isn’t resistant to errors. Machine imaginative and prescient excels in quantitative measurements on account of its precision, consistency and pace. As an illustration, when built-in right into a manufacturing line, a imaginative and prescient system can swiftly examine a whole bunch and even hundreds of elements per minute. Through the use of high-resolution cameras, machine imaginative and prescient programs can detect and look at minute object particulars that would go unnoticed by the human eye. Furthermore, machine imaginative and prescient eliminates the consequences of operator fatigue and particular person variances, making certain constant and dependable inspections.

- Reduces downtime. A imaginative and prescient system protects towards half harm by eradicating bodily contact between a take a look at system and manufactured elements. As put on and tear take their toll on mechanical elements, it additionally cuts down on the time and prices related to repairs. Machines function extra shortly as they require much less care, enabling firms to realize manufacturing deadlines constantly and simply.

- Lowers value. A machine imaginative and prescient system can increase manufacturing pace and scale back the labor essential to function the gear. It may possibly additionally reduce the scrap charge so much less supplies get wasted, which ultimately lowers the overhead.

- Improves office security. Machine imaginative and prescient mixed with AI improves office security by minimizing the necessity for human intervention throughout the manufacturing course of. When working giant, highly effective machines, staff are much less more likely to maintain accidents, and their contact with hazardous elements and supplies can be restricted.

- Detects flaws. Machine imaginative and prescient can detect product irregularities, similar to floor dents and scratches. By rigorously setting detection boundaries, it distinguishes between acceptable and unacceptable flaws.

- Measures precisely. A machine imaginative and prescient system can find and measure particular factors on a picture, similar to diameter, radius, distance and depth. For instance, this might assist decide the internal diameter of an engine cylinder bore or the liquid fill degree of a container. This info will be gathered with both 2D or 3D cameras.

- Identifies printing defects. A machine imaginative and prescient system can simply establish printing anomalies, similar to incorrect shade shades, blemished prints or lacking letters. The system begins by inputting a grasp or golden picture, which serves because the reference for all produced elements. Any deviations from the grasp picture are promptly recognized and flagged for correction, making certain correct and high-quality prints.

Machine imaginative and prescient in AI

AI is utilized in machine imaginative and prescient to expedite the decision-making course of. AI can course of a considerable amount of photographs and knowledge info that was beforehand too troublesome to assemble.

Examples of how AI is used with machine imaginative and prescient embrace the next:

- AI can help with signature and character recognition, which require a degree of nuance.

- In manufacturing, AI helps with object recognition and supplies inspection to allow machine imaginative and prescient programs to grasp acceptable variations within the form and texture of an object or materials.

- In high quality assurance, an AI-enabled system can interpret acceptable anomalies moderately than rejecting something that does not rigidly match one specification.

Machine imaginative and prescient in robotics

Machine imaginative and prescient, paired with AI and deep studying, expands the position of robots in performing production-line duties, similar to choosing, sorting, putting and performing a producing line scan. This mix of applied sciences additionally permits robotics to function in different environments, similar to supermarkets, hospitals and eating places.

Examples of how machine imaginative and prescient is utilized in robotics embrace the next:

- A robotic with machine imaginative and prescient can navigate the grocery store aisles, capturing stock knowledge about merchandise on the shop’s cabinets. It scans merchandise utilizing radio frequency identification (RFID) expertise to learn a barcode and might keep away from obstacles in crowded aisles. Amazon Go retail shops use machine vision-powered programs to watch stock and take a look at clients once they’re able to pay.

- Machine imaginative and prescient expertise permits automation, making it doable for course of sequences in varied purposes to be networked.

- Machine imaginative and prescient additionally makes collaboration between robots and people extra environment friendly and safer. For instance, in a grocery store, a robotic will be devoted to performing stock administration duties in order that human associates have extra time to help clients. The robotic can carry out stock scans extra incessantly than folks with higher accuracy. On an meeting line, robots with machine imaginative and prescient can analyze hazardous supplies and carry out different harmful duties with out exposing employees to unsafe situations.

- The info machine vision-enabled robots acquire and use will be processed within the cloud or on the edge of the community, enabling scalability and detailed knowledge evaluation.

What’s the distinction between machine imaginative and prescient and laptop imaginative and prescient?

In some circumstances, the phrases machine imaginative and prescient and laptop imaginative and prescient are used synonymously. In different circumstances, distinctions are made.

Machine imaginative and prescient is commonly related to industrial purposes of a pc’s capacity to see. The time period laptop imaginative and prescient is commonly used to explain any expertise during which a pc is tasked with digitizing a picture, processing the info it comprises and taking some sort of motion.

One other distinction that is typically made is in processing energy — that’s, the distinction between a machine and a pc. A machine imaginative and prescient system usually has much less processing energy and is utilized in Lean manufacturing environments, performing sensible duties at a excessive pace to accumulate the info wanted to finish a specified job. High quality management, inspection of things and guiding of objects via an meeting line are frequent purposes of machine imaginative and prescient.

Laptop imaginative and prescient programs acquire as a lot knowledge as doable about objects or scenes and purpose to completely perceive them. Laptop imaginative and prescient is best for accumulating basic, transferable info which may be utilized to a wide range of duties. It additionally will be carried out with out a digital camera because the time period can discuss with a pc’s capacity to course of photographs from any supply, together with the web. Frequent purposes of laptop imaginative and prescient embrace self-driving vehicles, studying barcodes and RFID tags, and inspecting for product defects.

Machine imaginative and prescient is without doubt one of the many purposes of AI in manufacturing. Be taught different methods manufacturing firms use AI to simplify enterprise processes and improve effectivity.