What’s an industrial management system (ICS)?

In industrial settings, industrial management system (ICS) is a time period used to explain the combination of {hardware} and software program with community connectivity to help manufacturing processes in manufacturing or vital infrastructure.

ICS is a basic time period for any system used to regulate and handle industrial processes, together with manufacturing, manufacturing and distribution. Because the mind of a manufacturing facility or plant, an ICS facilitates human-machine interactions.

Most ICSes embody several types of elements — units, controls, networks, and so forth. — that work collectively to realize a selected goal. A producing ICS could consist {of electrical}, mechanical and pneumatic elements to regulate product dealing with and manufacturing, whereas a chemical plant’s ICS could consist {of electrical}, mechanical and hydraulic elements to move materials or vitality.

What are the widespread kinds of industrial management methods?

The next are three of the commonest kinds of ICS.

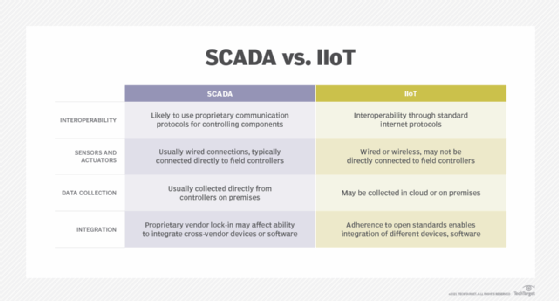

Supervisory management and information acquisition

Supervisory management and information acquisition (SCADA) supplies a centralized management system that facilitates the long-distance monitoring and management of area websites in settings like electrical energy distribution, water remedy and pipeline monitoring. SCADA methods embody elements like programmable logic controllers (PLCs) and human-machine interfaces (HMI).

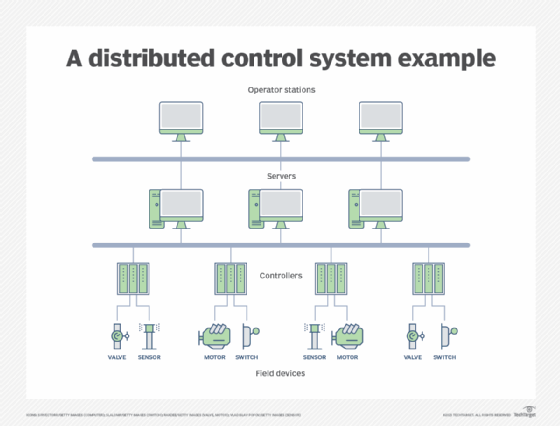

Distributed management methods

A distributed management system (DCS) is used to regulate a number of native manufacturing methods — units and controllers — utilizing a centralized supervisory management loop. The loop additionally permits plant managers to entry manufacturing and operation information for evaluation or decision-making. These methods are widespread in oil refineries, chemical manufacturing and water remedy amenities.

Industrial automation and management methods

An industrial automation and management system (IACS) can mechanically management manufacturing ranges primarily based on real-time information. This information is mechanically collected from a corporation’s gross sales or distribution channels. Like SCADA and DCS, an IACS combines {hardware}, software program and communication methods that collectively assist to transform information into actionable data. An IACS integrates a plant’s units, machines and tools and likewise connects these components with different components of the group, equivalent to its compliance processes, provide chain, and analysis and improvement division.

Industrial management system elements

Many ICS environments are a hybrid of DCS and SCADA. These methods sometimes embody the next:

- Programmable automation controllers. PACs are programmable computer systems that incorporate higher-level directions and execute embedded packages to regulate electromechanical processes and manufacturing facility equipment.

- PLCs. PLCs are small computer systems utilized in DCS and SCADA to regulate the system’s capabilities utilizing its inside logic and to automate sure processes.

- HMIs. PLCs and different SCADA elements are built-in with HMIs for centralized monitoring and management of the inputs and outputs of various processes. HMIs are often graphical person interfaces that permit human operators work together with {hardware}.

- Distant terminal items. RTUs are microprocessor-based area units that join {hardware} to a DCS or SCADA and ship sensor data to the grasp terminal unit.

- Management servers. They convey with lower-level management units over the ICS community and host the DCS or PLC supervisory management software program.

- Clever digital units. Utilized in SCADA and DCS to accumulate information, IEDs talk with different units and implement native processing and management actions.

- Management loops. They include {hardware} equivalent to PLCs and actuators, and so they interpret indicators from sensors and different units, in addition to transmit the knowledge to the controller to execute a sure activity or course of.

- Sensors. Sensors measure sure variables and generate indicators despatched to the ICS controller to execute some activity.

- Information historians. Information historians log all course of data in a centralized database to facilitate evaluation, course of management, planning and decision-making.

The place are industrial management methods used

Industrial management methods are utilized in nearly all industrial sectors, together with the next:

- Manufacturing.

- Chemical processing or manufacturing.

- Oil processing.

- Telecommunications.

- Meals and beverage manufacturing.

- Automotive.

- Prescribed drugs.

ICSes additionally help a nation’s vital infrastructure, equivalent to its electrical grids, public transportation, and water remedy, vitality and public communication methods.

All ICSes are constructed to electronically or mechanically execute and handle their assigned duties. The particular perform of every ICS will depend on its configuration, objective and industrial software space.

Evolution of commercial management methods

Traditionally, most equipment and engineering elements utilized in manufacturing and the operation of energy vegetation, water and wastewater vegetation, transport industries and different vital infrastructures have been “dumb.” Those who have been computerized sometimes used proprietary protocols. Additionally, the networks they belonged to have been air-gapped and protected against the surface world.

This has modified, and elements of immediately’s ICSes are sometimes related immediately or not directly to the web. This allows the assorted elements to speak with one another and with different methods not a part of the native community. Early ICSes provided solely localized management and barely supplied an total view or management over a complete manufacturing system.

Extra lately, ICSes that provide centralized management or distributed management emerged. The previous makes use of a centralized management room that gives an outline of the complete system. The latter harnesses computerized and autonomous controls distributed all through the system to localize management capabilities close to the machines, whereas enabling distant monitoring and supervisory management.

Right now, ICSes are advanced, highly effective methods indispensable to plant operations in all types of industries. Increasingly more are a part of the web of issues (IoT), which improves their usability, effectivity, productiveness and velocity.

Industrial management methods, data expertise and operational expertise

Advances in sensible sensor expertise and wi-fi networking have made the mixing of operational expertise (OT) with data expertise (IT) fascinating and cost-effective. This IT/OT convergence permits industrial organizations to get higher visibility into and management over their provide chain. It additionally enhances system performance and boosts total productiveness. It provides advantages like elevated velocity, higher responsiveness to altering situations and improved reliability.

Regardless of these advantages, there’s one severe disadvantage of IT/OT convergence: safety dangers.

Industrial management methods safety

IT/OT convergence creates quite a few alternatives for risk actors to assault and compromise ICSes. They’ll exploit vulnerabilities in a number of internet-connected units to realize direct entry to them and compromise a number of processes. They might additionally execute phishing assaults and ransomware assaults or transfer laterally throughout the community to determine a long-term presence in it, making it potential to steal information or spy on the group.

Focused assaults towards ICSes, notably vital infrastructure ICSes, pose a risk to most nations around the globe. As distant telemetry items used to enter change turn into extra able to native management and as IoT and industrial IoT develop, it turns into more and more vital to guard ICSes from safety threats.

In america, the Division of Homeland Safety provides these suggestions to guard ICSes:

Distinctive and customary cybersecurity threats and challenges goal industrial management methods. Be taught in regards to the high ones right here and mitigate them by exploring the high 10 ICS cybersecurity threats and challenges.