What’s operational expertise?

Operational expertise (OT) is a class of {hardware} and software program that displays and controls how bodily gadgets carry out.

Previously, OT was used primarily in industrial management techniques for manufacturing, transportation and utilities. In contrast to IT, the expertise that managed operations in these industries wasn’t networked. Most of the instruments for monitoring or adjusting bodily gadgets have been mechanical, and people who had digital controls used closed, proprietary communication protocols.

Nevertheless, as bodily gadgets have gotten sensible, there may be an rising pattern towards IT/OT convergence. Wi-fi connectivity has supplied directors in control of OT with higher monitoring techniques and the flexibility to regulate bodily gadgets remotely. Advances in machine-to-machine communication and machine studying have created a notable change, enabling the information that bodily gadgets produce to be analyzed in actual time to facilitate autonomy, preventive upkeep and improved uptime.

Web-capable expertise has moved into industrial management techniques (ICS) and supervisory management and knowledge acquisitions (SCADA) networks. Nevertheless, operations expertise faces the identical malware, id administration and entry management safety challenges that IT faces. The distinction is that vulnerabilities in an OT system can go away vital infrastructure prone to sabotage that may end up in life-or-death conditions.

Why is operational expertise essential?

OT is vital for companies and society at giant. On the organizational stage, OT is normally tied to core enterprise processes. In a manufacturing facility, OT is usually the software that makes manufacturing items attainable. Likewise, hospitals rely upon OT gadgets to diagnose sufferers. For a enterprise or different group that depends on OT, downtime brought on by service outages can severely impair and even halt the group’s core enterprise actions.

On a broader stage, society is determined by OT to maintain vital infrastructure functioning. For instance, in Could 2021, a ransomware assault brought on the Colonial Pipeline to be shut down. The pipeline, which itself is taken into account an OT, transports 2.5 million barrels of gasoline every day. The shutdown resulted in a significant East Coast gasoline scarcity. This is only one instance of how vital some operational applied sciences may be.

Examples of OT environments

Many industries depend on vital OT infrastructure. Some OT environments embody the next:

- Factories. OT controls the equipment utilized in manufacturing environments to energy meeting strains and different processes.

- Energy crops. OT techniques monitor each the efficiency and useful resource use of apparatus utilized in energy crops.

- Oil and gasoline refineries and pipelines. The oil and gasoline trade requires vital OT infrastructure for upstream, midstream and downstream operations. OT displays rigs, pumps and different extraction strategies inside upstream operations. It additionally performs distant asset administration when oil and gasoline is transported, refined and saved throughout operations.

- Transportation and aviation services. Provide chain administration, commuter transport and aviation all depend on OT to maintain transport operations working easily.

- Water therapy services. OT controls processes concerned with wastewater therapy.

Examples of OT techniques

It is simple to think about operational expertise techniques as intently related to industrial gear and, certainly, they’re closely used on manufacturing facility flooring and energy crops. Nevertheless, they don’t seem to be restricted to industrial processes. An OT system may be any particular function, computerized gear. For instance, ATMs, security techniques and site visitors lights are all such techniques that are not a part of conventional IT infrastructure and are thought of OT techniques.

Different examples of OT techniques embody the next:

- Robots. Industrial robotics, corresponding to cobots, are thought of OT techniques, as are robots which might be more and more utilized in retail for stocking cabinets or mopping flooring.

- Medical gadgets. Sure medical gadgets, corresponding to magnetic resonance imaging machines and different forms of radiology gear, are thought of OT gadgets.

- Distributed management techniques. A DCS is used to regulate the automation of business operations. Controller gadgets are unfold throughout a manufacturing facility or plant flooring to handle every course of individually.

- Human-machine interfaces. HMIs assist operators monitor OT environments visually with visible shows of information, a management panel for interplay and sometimes a notification setup for essential alerts.

- ICS. These techniques handle and monitor OT networks, together with the infrastructure and processes they embody. They use network-connected {hardware} and software program elements.

- Industrial web of issues. IIoT techniques join bodily gadgets and objects to IT networks, letting them acquire knowledge and carry out predictive upkeep on them. IIoT is a subset of web of issues. IoT and industrial IoT are each related to OT environments, however IIoT is particular to industrial environments.

- Programmable logic controllers. A PLC automates varied industrial processes and might operate in harsh environments, corresponding to excessive warmth, chilly or vibration.

- Distant terminal items. RTUs are used for knowledge assortment and administration in OT environments.

- SCADA. These techniques seize real-time knowledge from OT, by way of each software program and {hardware} elements, for the aim of monitoring efficiency.

- Sensible buildings. These services are enterprise, business and residential buildings geared up with automated IoT expertise for varied causes, corresponding to working effectivity, security and safety.

- Sensible transportation. IT networks are used to watch the efficiency of assorted modes of transportation. Linked gadgets on autos can present knowledge site visitors, climate situations and different elements to create extra environment friendly routes and enhance car effectivity.

Operational expertise challenges

As organizations work to converge IT and OT techniques, they have to concentrate on the inherent challenges of doing so. Many of those challenges stem from the character of the OT techniques getting used. They embody these 4.

Legacy points

Though some OT techniques are fashionable and complicated, it is also frequent — notably in industrial settings — for OT gear to be a number of many years outdated. When you think about such a tool’s age and its proprietary design, it may be troublesome and expensive to attach the system to fashionable IT techniques.

Cybersecurity dangers

One other problem related to these mixtures is that they will introduce OT cybersecurity dangers. That is very true for legacy OT techniques. Such techniques have been doubtless by no means meant to be linked to a company’s IT techniques. Normally, they have been meant to function in an remoted setting and did not want safety towards cyberthreats.

As a substitute, the design course of doubtless targeted on making the system as dependable as attainable, somewhat than addressing safety threats. Connecting such techniques to conventional IT infrastructure could make them weak to cyberattacks, as a result of hackers have a direct communications path by way of which to entry the system. Organizations trying to converge their IT/OT infrastructure should put OT safety measures on the forefront.

Data gaps

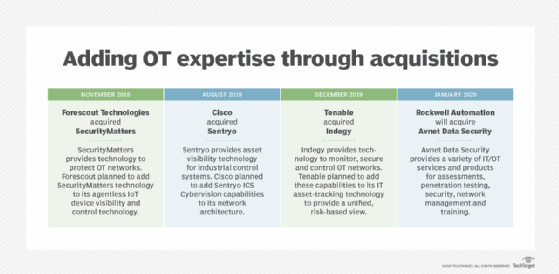

One other problem is addressing any data gaps. OT engineers are unlikely to be specialists in IT. Equally, few IT professionals have a robust working data of OT techniques.

Replace and patch administration

Lastly, OT gadgets may not match neatly into a company’s regular IT protocols for software program updates and patch administration. For instance, patch administration is usually thought to be a vital IT process. Nevertheless, patches for OT gadgets could be launched on an rare foundation or by no means.

Even when an OT system producer releases a patch, there’ll doubtless be some pushback over putting in the patch. At greatest, putting in the patch will trigger a service interruption whereas the system is taken offline and rebooted, which impacts the group’s income. At worst, the patch can introduce issues into a tool that was beforehand dependable, once more, adversely affecting the group’s backside line.

OT vs. IT: What are the variations?

IT environments have historically targeted on compute, networking and storage sources. These sources embody servers, storage arrays and community switches within the knowledge heart or the cloud in addition to desktop computer systems, sensible telephones and supporting {hardware}. Enterprise IT can also be answerable for managing software program on the infrastructure and utility ranges. This implies deploying and sustaining working techniques, IT safety controls and monitoring instruments, and the functions customers depend on to do their jobs.

Conversely, OT encompasses the machines related to bodily processes. These processes may be something from the manufacturing of products to medical imaging. Like IT, they revolve round using digital techniques. Nevertheless, these techniques are typically proprietary and do not typically fall into the scope of conventional IT belongings.

IT/OT convergence

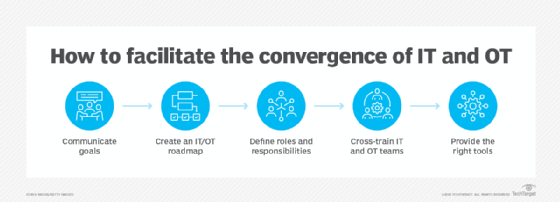

IT/OT convergence entails linking operational applied sciences to conventional IT techniques. Bringing these techniques collectively could make it simpler for a company to fulfill its compliance mandates, whereas additionally breaking down knowledge silos. Nevertheless, there will also be different, extra compelling advantages.

Linking IT techniques to OT gadgets brings intelligence to varied enterprise processes. In a manufacturing facility setting, a converged IT/OT system can analyze your entire manufacturing course of to identify inefficiencies. Detecting and eliminating these inefficiencies, in the end, makes the enterprise extra worthwhile.

Likewise, IT techniques can monitor OT gear use to see when the gadgets will want upkeep primarily based on their use. This prevents machines from breaking down and saves the enterprise cash.

The position of edge computing in IT/OT convergence

Edge computing entails deploying computing gadgets a lot nearer to sources of information to scale back challenges related to distributed techniques the place computing capabilities are additional away from the information sources. Edge computing enhances OT techniques in a number of methods, corresponding to the next:

- Actual-time analytics. Edge computing reaches knowledge sources in distant places and analyzes it from these places so not as many IT and OT sources are expended.

- Safety. Edge computing techniques sit in between OT gadgets and IT networks, utilizing intrusion detection capabilities to establish cyberattacks. Additionally they can cut back the quantity of information transmitted between OT and IT gadgets and networks in order that solely important knowledge is shipped and secured. This reduces pointless alternatives for knowledge breaches and different safety incidents.

- Decentralization. Edge computing usually strikes IT and OT sources to the cloud so there’s much less reliance on centralized bodily infrastructure that may be liable to issues. This ends in extra dependable techniques as properly.

- Lowered latency. Knowledge is processed and analyzed nearer to the supply, decreasing the time and sources IT should commit to doing so.

- Decrease bandwidth. By minimizing the quantity of information that is transferred to solely important knowledge, edge computing reduces the quantity of bandwidth that might in any other case be required to transmit giant knowledge volumes.

Companies that rely closely on OT networks and infrastructure ought to concentrate on 5 potential OT threats and safety challenges and know how one can reply after they come up. Be taught what these challenges are to be proactive in securing OT.