Lean undertaking administration is a technique targeted on maximizing worth whereas minimizing waste all through a undertaking’s lifecycle. The lean strategy is centered round effectivity. It’s all about slicing out the fluff — whether or not that’s pointless steps, wasted sources, or downtime — and specializing in what provides probably the most worth.

What’s lean undertaking administration?

Impressed by the Toyota Manufacturing System (TPS) within the mid-Twentieth century, lean rules had been initially utilized to manufacturing however have since expanded to different industries, together with undertaking administration. You possibly can consider lean undertaking administration as a “less is more” strategy to operating tasks.

This implies fewer sources are used to generate extra worth by eliminating inefficiencies and constantly enhancing processes. Lean undertaking administration seeks to streamline workflows and guarantee every activity will get you nearer to delivering precisely what your buyer wants with out further baggage weighing you down.

5 rules of lean undertaking administration

Lean undertaking administration revolves round 5 core rules that information groups in delivering worth with out the litter.

Specify worth

The primary precept has you reply, “What am I really delivering to my customer?”

Understanding the actual worth you’re delivering to the shoppers, whether or not exterior or inside, entails digging into what they really care about and could be keen to pay for. For undertaking groups, this implies aligning efforts with the shoppers’ priorities and ensuring that every activity instantly contributes to the tip aim.

As an illustration, in software program tasks, this might contain specializing in options that resolve essential consumer ache factors reasonably than including pointless or ineffective options. One other instance could be a gross sales undertaking that facilities round iterating a particular side of the sign-up course of that impacts a focused demographic.

Map the worth stream

When you’ve pinpointed the worth, it’s time to map out your entire course of from begin to end. Within the lean methodology, this is called the worth stream.

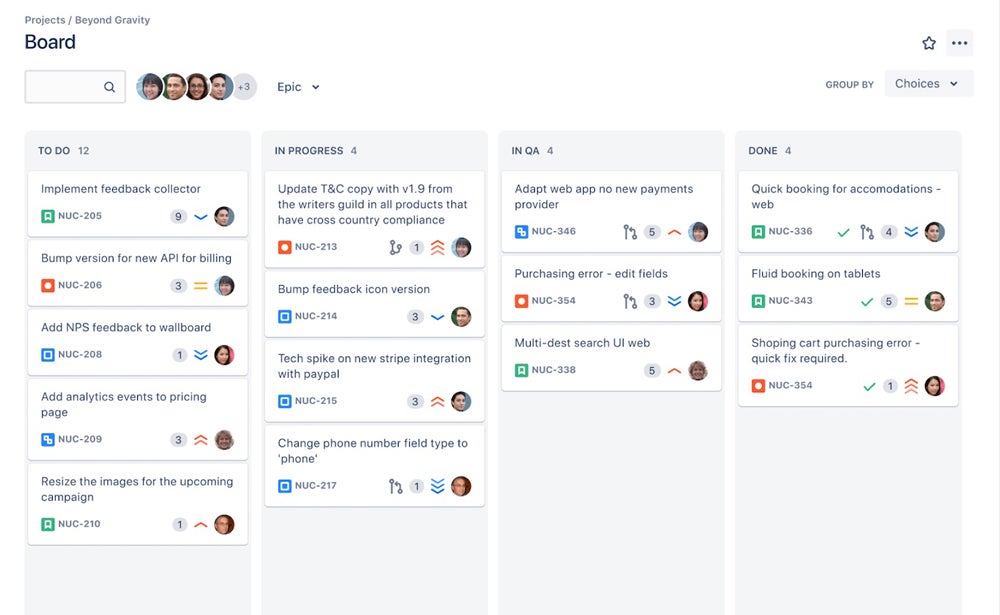

Mapping the worth stream isn’t nearly itemizing duties, however about figuring out each step that provides worth and eliminating waste wherever attainable. A standard software used for that is the kanban board, which is kind of standard in agile undertaking administration software program.

A kanban board visually represents a workflow and helps groups see the place bottlenecks or delays may happen. This step encourages transparency in operations and permits your groups to refine processes because the undertaking evolves.

For these managing extra structured processes like waterfall undertaking administration, mapping the worth stream might help to establish areas the place delays or inefficiencies generally happen.

Create movement

Stream is the center of lean undertaking administration. After figuring out and slicing out waste, you need to introduce a good sequence by making a course of the place duties transfer seamlessly from one stage to the subsequent with out pointless delays.

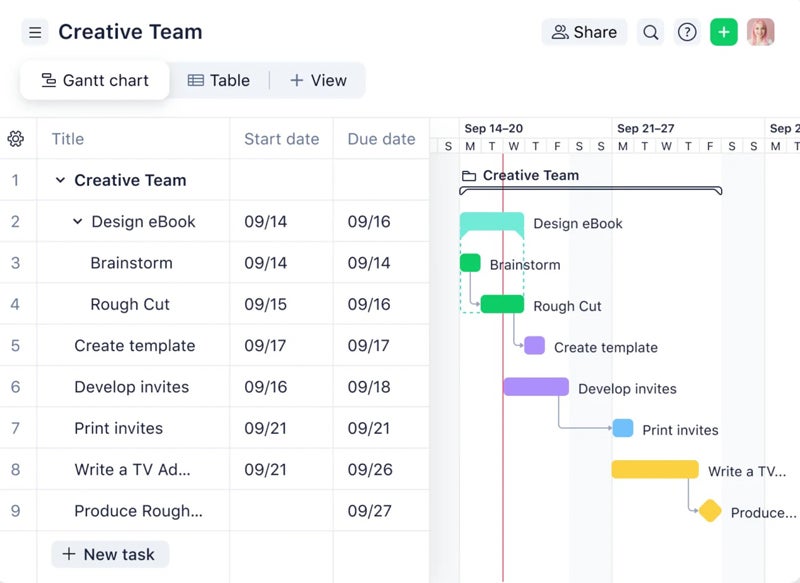

Some undertaking groups will use a Gantt chart to visualise the movement and higher see how steps within the undertaking relate to one another. This kind of software is especially helpful for tasks with numerous activity dependencies.

A technique to make sure movement is by addressing bottlenecks. The place does work are inclined to pile up or decelerate? For instance, a group may discover that too many approvals or handoffs between departments are inflicting delays and rework the method to keep away from these choke factors. Or they might uncover that the workload isn’t balanced amongst group members and modify that to extra evenly distribute duties.

SEE: Study extra about Gantt charts and the way they are often utilized for lean undertaking administration.

Set up pull

The fourth precept of lean undertaking administration builds on the idea of just-in-time manufacturing. As a substitute of pushing work by the pipeline, lean emphasizes a “pull” system, the place duties are initiated solely when there’s a demand for them.

This retains the group from overproducing or losing sources on options or duties which may not be wanted. In undertaking administration, a pull system ensures that sources and time are allotted effectively, focusing solely on what provides worth within the second.

Pursue perfection

Lean undertaking administration isn’t nearly getting issues carried out — it’s about constantly enhancing the best way issues are carried out. In consequence, this precept encourages a tradition of ongoing reflection and refinement.

After the profitable completion of every undertaking, and even throughout it, groups ought to ask what labored effectively, what didn’t, and the way issues may be improved transferring ahead. It’s about striving for perfection by small, incremental modifications, also known as kaizen, which assist groups keep versatile and environment friendly.

Advantages of lean undertaking administration

Better effectivity and fewer wastage are the first objectives of the lean methodology, however there are some further advantages to additionally contemplate. Listed below are among the high advantages of lean undertaking administration.

- Elevated effectivity: By specializing in eliminating waste and streamlining processes, lean helps groups work extra effectively. Duties are accomplished sooner, bottlenecks are lowered, and pointless steps are lower, which results in smoother undertaking supply.

- Value discount: Lean is designed to establish and remove wasteful actions, which instantly reduces prices. Groups keep away from overproduction, pointless useful resource use, and delays that may add monetary pressure to tasks.

- Enhanced buyer satisfaction: Since lean focuses on figuring out and delivering what the shopper actually values, the tip result’s a services or products that meets their actual wants. This results in higher buyer satisfaction and can even foster stronger relationships with shoppers.

- Improved adaptability: Lean promotes steady reflection and enchancment, making it simpler to adapt to new data, modifications in scope, or sudden challenges. The methodology encourages groups to stay versatile, adjusting plans and processes as wanted.

- Quicker supply occasions: With lean’s concentrate on making a clean movement and eliminating delays, undertaking timelines may be shortened with out sacrificing high quality. That is particularly helpful in industries the place time-to-market is essential.

Ought to your group use lean undertaking administration?

If your organization typically faces useful resource constraints, tight deadlines, or fluctuating undertaking calls for, you must contemplate lean undertaking administration as a structured technique to prioritize what issues most and remove what doesn’t.

Moreover, lean’s capacity to shortly adapt to modifications permits organizations to pivot effectively with out including vital overhead or delays. By specializing in what provides worth to the shopper and consistently enhancing processes, companies can keep agile and aggressive of their markets.

As for corporations in industries akin to manufacturing, software program growth, healthcare, or development, the place waste and inefficiency have a huge effect on the underside line, lean undertaking administration could be significantly helpful.

Whether or not your aim is price financial savings, sooner supply occasions, or just a extra engaged and environment friendly workforce, the lean methodology is a confirmed technique to meet these aims.

For a take a look at complete undertaking administration instruments that might improve lean practices, take a look at this listing of the high undertaking administration software program of 2024.

Ceaselessly requested questions (FAQs)

What’s the distinction between lean and agile?

Lean and agile undertaking administration share some commonalities, akin to their emphasis on flexibility and steady enchancment, however they differ in focus and execution.

- Lean goals primarily at eliminating waste and optimizing processes for effectivity, whereas agile focuses on adaptability and delivering working increments of a undertaking shortly.

- Agile is extra iterative, with brief cycles of growth, overview, and adaptation, whereas lean is about making a value-driven, waste-free movement.

- Lean typically influences agile practices, however agile tends to focus extra on frequent supply and suggestions loops.

Is scrum lean or agile?

Scrum is primarily an agile methodology. It focuses on delivering work in brief cycles or sprints, the place groups repeatedly reassess and adapt based mostly on suggestions. Nevertheless, some parts of scrum align with lean rules, akin to minimizing waste and emphasizing steady enchancment. Nonetheless, scrum’s core framework is constructed round agile values and rules.

Is kanban agile or lean?

Kanban has roots in lean manufacturing however is extensively utilized in agile environments right now. Kanban is concentrated on optimizing workflow and lowering bottlenecks, which is a core lean idea. Nevertheless, it’s now typically used inside agile groups to visualise work and handle movement, making it appropriate with each methodologies. Due to this fact, whereas kanban comes from lean considering, its flexibility makes it helpful for agile practices.